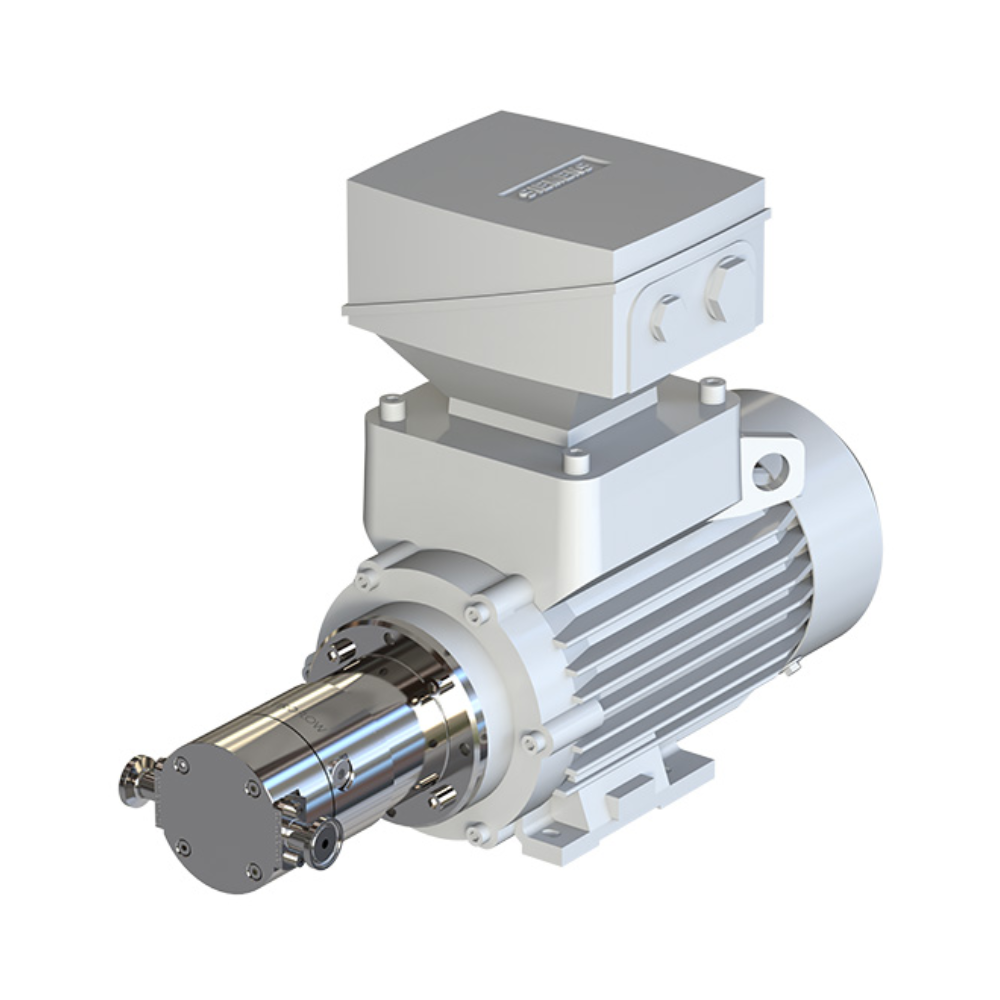

Diaphragm pump

Alflow offers a wide range of sanitary, industrial and single use diaphragm pumps for a variety of applications. We have pumps that have high chemical resistance, are suitable for transporting aggressive media, can withstand dry running and are easy to maintain. That's why it's a widely used pump type.

The pumps are made of durable materials that help ensure an efficient experience. Check out the range of diaphragm pumps from leading manufacturers on this page and transport your fluid in the best way possible.

What is a diaphragm pump?

Diaphragm pumps that are Positive displacement pumps, are widely used because of their versatility. They have good self-priming properties, are suitable for ATEX applications, and handle low-viscous, high-viscous and particulate fluids. Diaphragm pumps come in several different variants, materials and sizes. They are available in aluminium, stainless steel, acid-proof steel, PP and PVDF.

Where are diaphragm pumps used?

The diaphragm pump is versatile and designed to handle both low and high-viscosity products in food production, beverage production, chemical manufacturing, pharmaceutical manufacturing, dosing, dispensing and moving and transporting liquids with varying viscosity and with/without particles. For example, it is compatible with abrasive liquids, corrosive liquids, chemicals, paints, ceramics, powders and more.

Find the right diaphragm pump for your process

A diaphragm pump can of course be used for several different purposes. Below we have listed some of the places where you can use a diaphragm pump:

- Food production

- Beverage production

- Chemical manufacturing

- Pharmaceutical manufacturing

- Dosage

- Dispensation

- Moving and transporting fluids with varying viscosity and with/without particles

Our air-operated diaphragm pumps are available in both plastic and metal for a wide range of applications.

Among other things, we have diaphragm pumps with a plastic centre block. These pumps are suitable for strong acids and aggressive media.

Diaphragm pumps are also available with a closed fusion diaphragm for higher safety against leakage into the pump, and some pumps are designed for CIP.

Media for diaphragm pumps

The diaphragm pump is versatile and designed for pumping both low-viscous and high-viscous products - and both with and without particles. It is compatible with many different media, for example:

- Abrasive liquids

- Corrosive liquids

- Chemical products

- Painting

- Printing inks

- Lacquer

- Ceramics

- Powder

- Solvents

- Liquids with solid particles

- Food products

- With more

How to operate a diaphragm pump

Depending on the fluid to be pumped, you can choose between different diaphragm materials - diaphragms are available in PTFE, Nitrile, EPDM and Viton, for example.

Diaphragm pumps are designed with few moving parts, which contributes to high reliability, long service life and easy maintenance. Some of the diaphragm pumps are also equipped with wing screws for quick and easy disassembly.

Our air-operated diaphragm pumps are powered by compressed air, which helps to extend the life of the pumps. The pumps are self-priming, which means they can run dry and pump up against a closed valve. Our pumps can also be controlled and regulated in relation to air flow and air pressure using simple equipment.

Our Quattroflow diaphragm pump is unique in the way it pumps fluids for safe, reliable and efficient transfer of biological materials. The technology is designed to mimic the human heart. The low friction, low shear and low pulsation and a corresponding minimal temperature increase of the medium, gives the pump a smooth flow and makes it ideal for critical applications in biopharmaceutical production. The pump can be installed with an interchangeable single-use pump chamber, enabling the pump and production to make quick changeovers and meet rapid speed-to-market demand.

How to find the right diaphragm pump?

To ensure a correct pump selection for the process, it is important to consider all necessary process and site data as well as customer preferences. Among other things, it is important to know the process type, capacity, pressure, flow, head, NPSHa, cavitation risk, voltage supply, frequency, installation conditions and fluid data such as temperature, viscosity, abrasives, solids, etc.

Buy diaphragm pumps from Alflow

We focus on giving you a good experience at Alflow. That's why you'll find diaphragm pumps of the highest quality from recognised manufacturers. This means that our diaphragm pumps meet the requirements of various industries. That way, you can count on a good experience with the diaphragm pump.

You can choose to have the pump delivered with the applicable certificates suitable for several industries. Our diaphragm pumps can be supplied with, among other things:

- FDA

- 3A

- ATEX

- USP Class VI

- With more

At Alflow, we have over 20 years of experience with processes, applications and components in industries such as the food and chemical industries. So if you need a pump to transport water or chemical media, you can find it at Alflow. Would you like to know more? Our specialists are ready to help you find the right diaphragm pump and work with you to find the best match for your application. You can easily Contact us on this page.

See also our other pumps

Do you or your customers need a pump for a different application? Then you can explore The range of pumps. At Alflow you can find, among other things:

- Centrifugal pumps

- Lobe pumps

- Piston pumps

- Screw pumps

- Gear pumps

- Eccentric pumps

- Dosing pumps

We have pumps for a myriad of purposes, and you can find them at Alflow. We also carry a wide range of other flow products such as valves, hoses, mixers, flow meters, pipes & fittings and more, so you can get a complete solution from us. We are a recognised supplier of high-quality products. At Alflow, we comply with the applicable requirements and standards in several industries. That way, you and your customers get an efficient and optimal experience with our products.

We always strive to find the most perfect solution for your application so that we can contribute to a higher yield in your production through less maintenance and less downtime. If we can achieve this together, we fulfil our goal of being your value-adding partner.