Few control on Steam In Place and leather, how to the avoids temperature error and repetitions i sterile processes. See, how to and SSC can make the difference.

SIP: Avoid errors and achieve stable sterility in pharma and food

SIP - how to avoid validation errors and ensure sterility

Steam In Place (SIP) is decisive for sterile processes i pharma and food production. Men what happens there, when temperatures teasing - and how to avoids you that should repeat Processes?

What is SIP - and why it is Important?

When producing food or medicine, the facility must be completely clean - not just clean to look at, but free from any kind of microbiological activity. This is where SIP (Steam in Place) comes in.

SIP is a process where pure steam sterilises the entire system. This happens after CIP cleaning and before the next batch. The goal? To ensure that every drop running through the system has a sterile environment all the way.

Why do SIP processes fail?

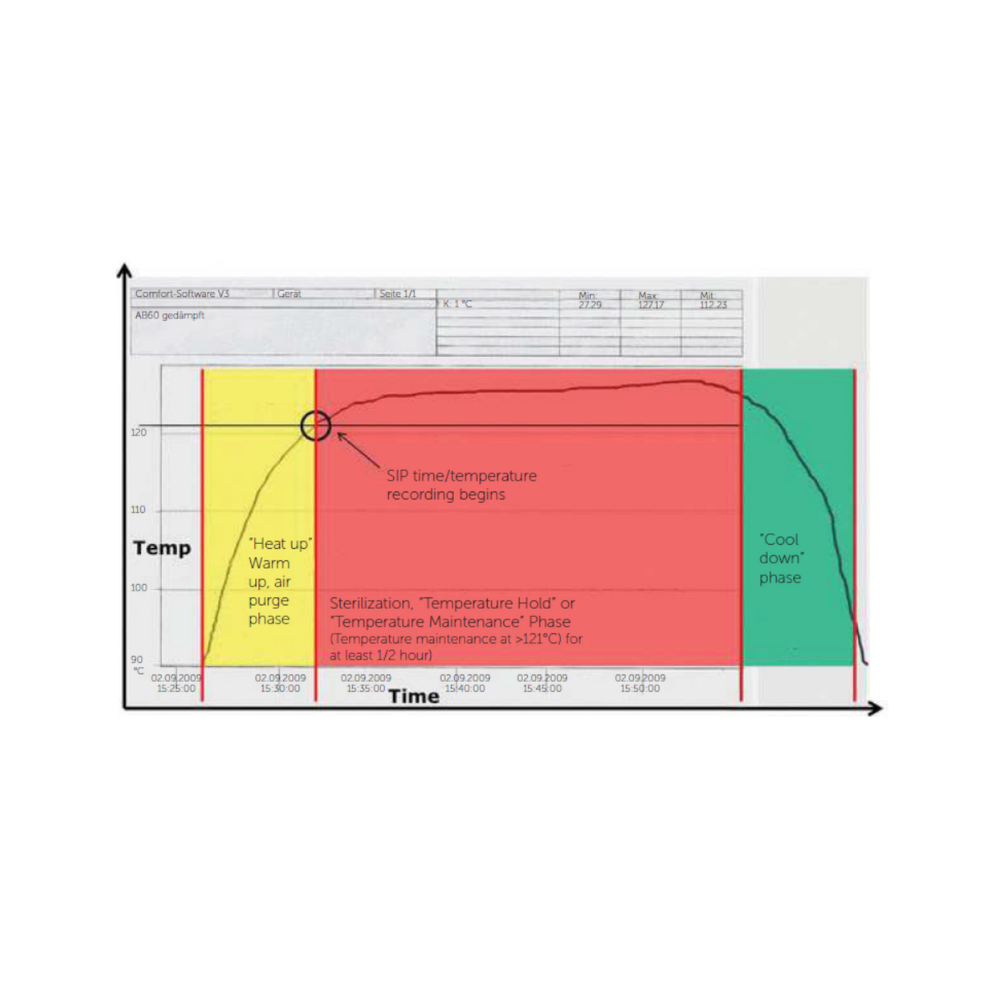

In order to SIPProcesses can is approved, shell temperatures is documented. The facility shell Keep it clean at least 121°C i 30 minutes - without interruptions. If temperatures fall under the border, registered the as and validation errors, and SIP shell starts From the front.

Tree typical Causes to temperature validation error

It's almost always condensate that interferes with the temperature sensor:

- If there is not enough space between sensor and water discharger

- If a faulty water discharger lets steam through

- If multiple water dischargers share the same condensate system

... the condensate can collect and cool down the sensor - and then the validation fails.

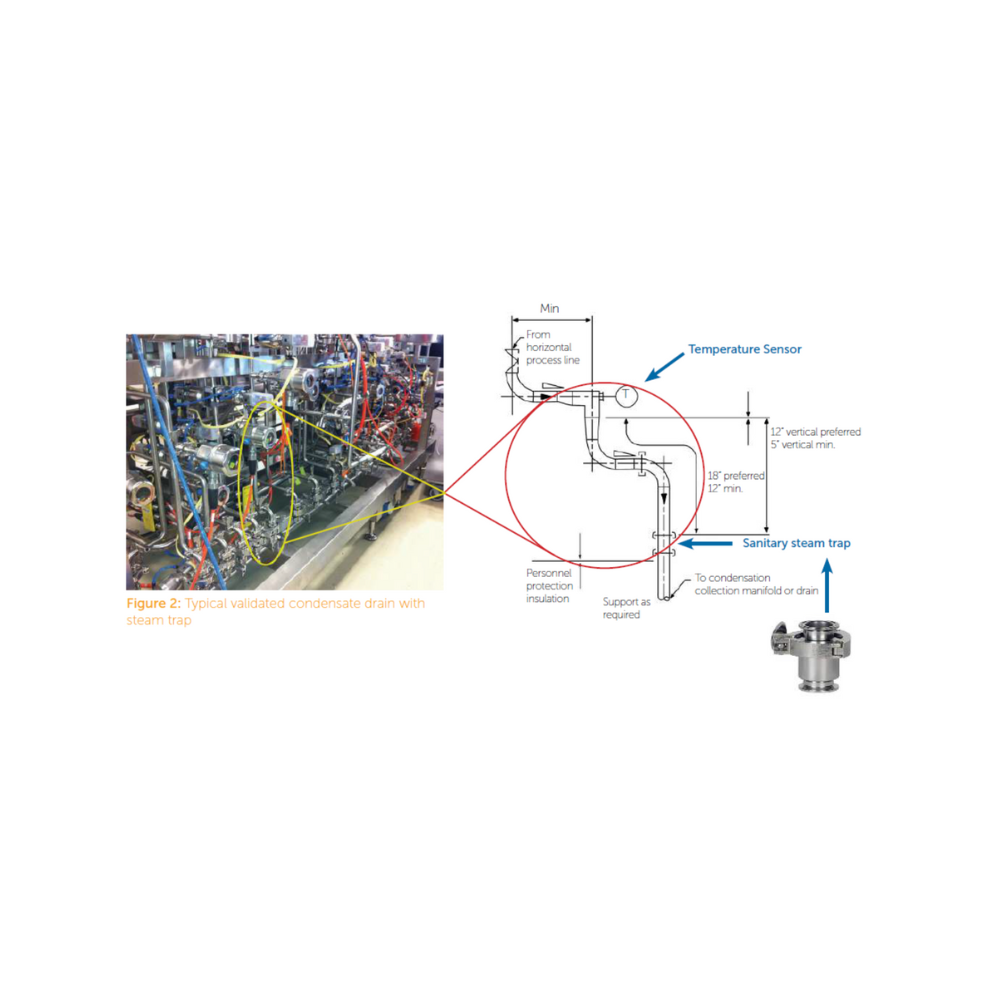

What can you do?

Fortunately, there are several solutions:

- Use water dischargers with low subcooling

- Ensure 300-450 mm between sensor and water discharger

- Replace faulty components quickly

- Design the condensate system with capacity for peak loads

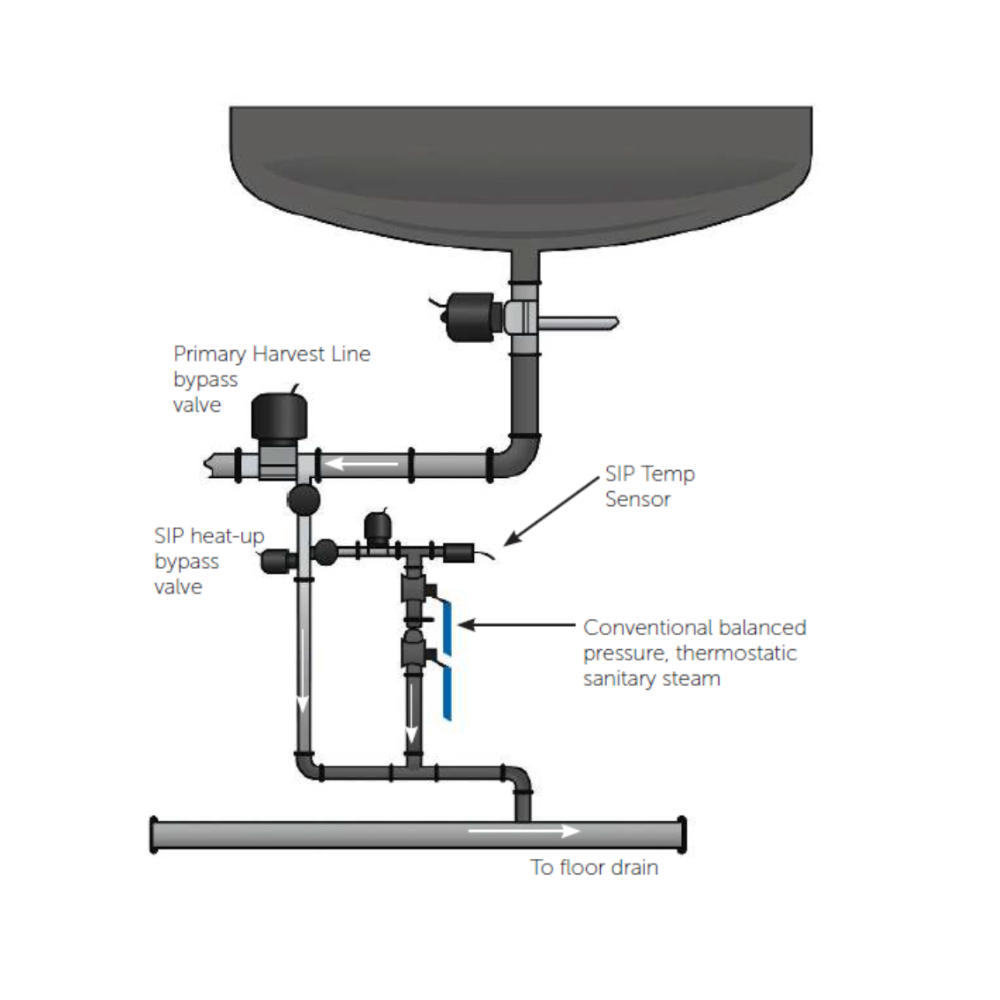

When the not is Space - then does debt

In many installations - especially under tanks - there is no room for the ideal pipe run. Here there are two ways forward:

- Utilise horizontal space: Even short, slightly inclined horizontal pipes can form a buffer that protects the sensor.

- Install a sanitary condenser: This is where the SSC - the sanitary condenser - comes in.

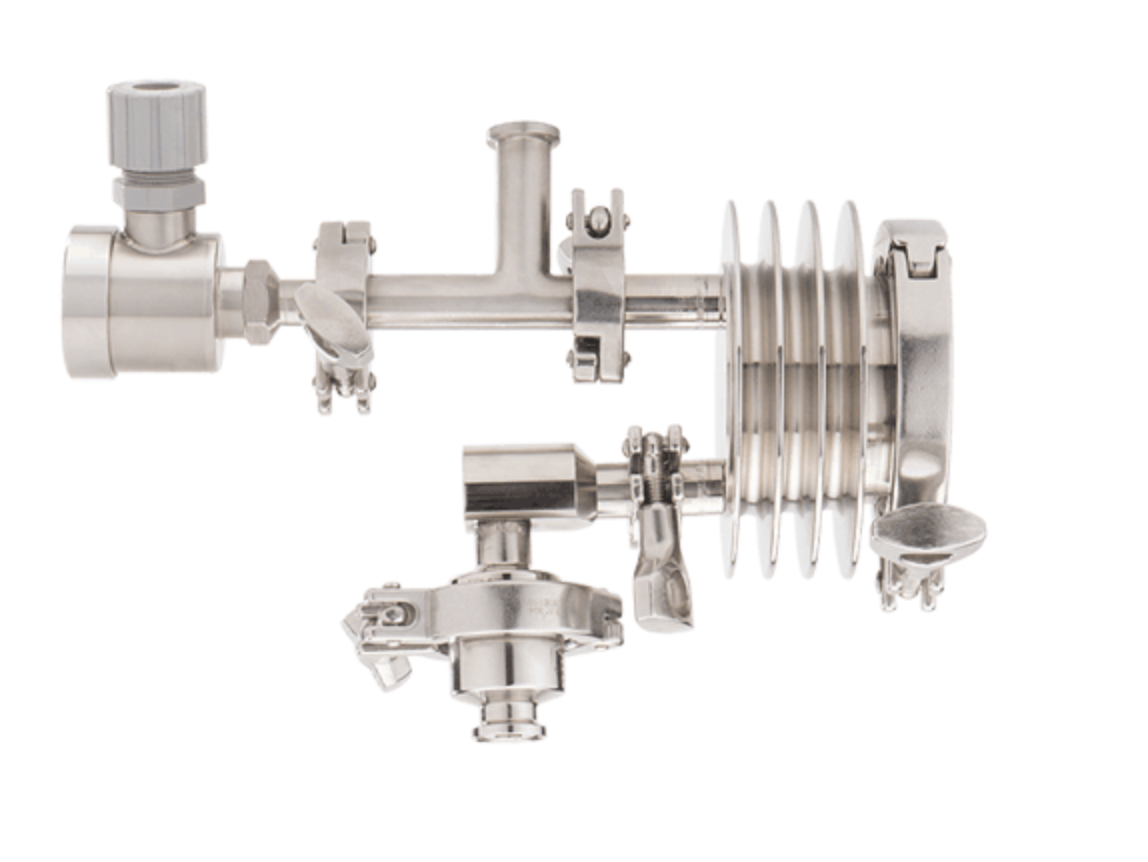

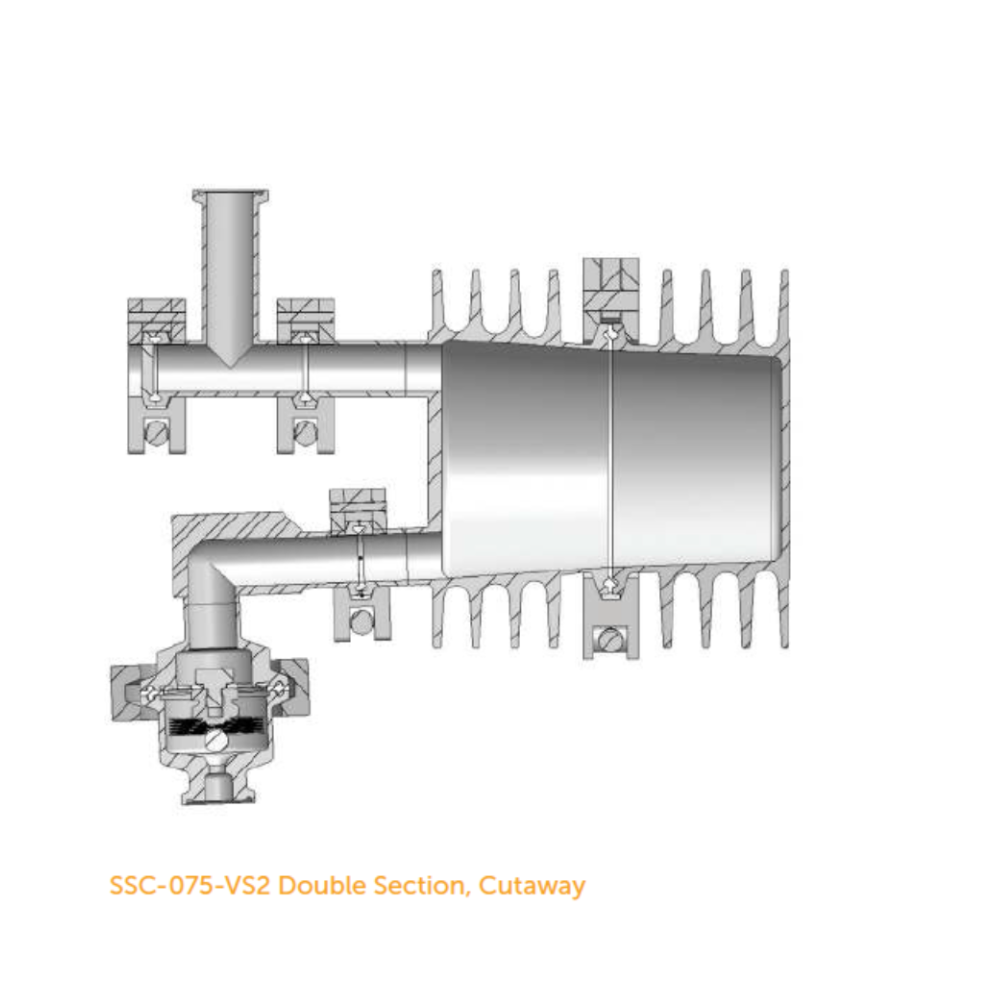

How a sanitary condenser (SSC) works

SSC collects and cools the condensate before it reaches the water discharger - and that makes a world of difference.

The benefits in practice:

- Eliminates the risk of validation errors

- Shortens heating time

- Requires minimal space

The SSC has cooling fins and a large surface area that effectively extracts heat from the condensate - so the steam bellows work as it should. And you can get validation the first time, every time.

Ready to optimise your SIP process?