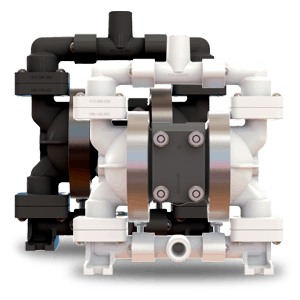

When faced with choosing a pump for pharma, food or cleanroom applications, I often get the question: Why a diaphragm pump? Here I give you my top nine reasons - based on the knowledge and experience we advise our customers with every day.

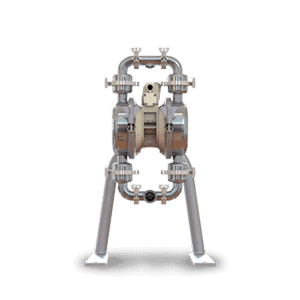

9 good reasons to choose a diaphragm pump

That's why a diaphragm pump (AODD) is often the best choice:

1. Low purchase price

Compared to many other pump types, you get a lot for your money. The simple design and low maintenance requirements make diaphragm pumps an economically attractive choice - also in the long term.

2. High reliability

AODD pumps have few moving parts and no electrical components. This minimises the risk of breakdowns and makes them particularly suitable for critical processes where continuous operation is essential.

3. Versatility

They can handle everything from water and foamy liquids to viscous, particulate and aggressive media. I have customers who use the same pump for multiple media types, which makes operations more flexible.

4. Compatible with aggressive chemicals

With the right choice of material, AODD pumps can withstand even the most challenging liquids. We often see them used in CIP solutions and when dosing acids and bases in pharma.

5. Particle resistant

This flow without a rotor or impeller means that particles in the media do not damage the pump. This is especially relevant in processes with pulp, fibres or protein lumps.

6. Simple maintenance

The pump can be disassembled quickly, without special tools. This saves time and reduces service costs. I often recommend AODD in facilities where frequent cleaning is required.

7. Submersible

In wash zones and clean room installations, the ability to place the pump below the liquid surface is a big plus. A customer in the food industry gained much more flexibility after switching to the AODD pump.

8. Dry run safe

Diaphragm pumps can run without fluid without damage. This reduces the risk of damage in case of accidental downtime or empty suction.

9. Closed fusion membrane

This maximises process and product safety. The risk of contamination or media leakage is minimised - essential in sterile and validated applications.

How a diaphragm pump works - see it in practice

Want to see how an AODD pump really works? The video below shows how compressed air and the diaphragms create pulse-by-pulse pumping power - with no electrical parts and minimal wear and tear.

"When explaining how a diaphragm pump works, this video gives a quick and clear picture of the principle behind it - and why it is both reliable and versatile."